Elastic Interface® N3X Technology: Changing the Game Once Again

[ssbp]Elastic Interface® takes pride in our dedication to constantly evolving the way we define cycling protection. It is our attitude and what we consider innate to who we are. When we first introduced the elastic chamois it revolutionized a world of pads made of suede leather. And over the years, we stayed true to our commitment to adopting cutting-edge technologies in innovating cyclist protection and performance in the saddle.

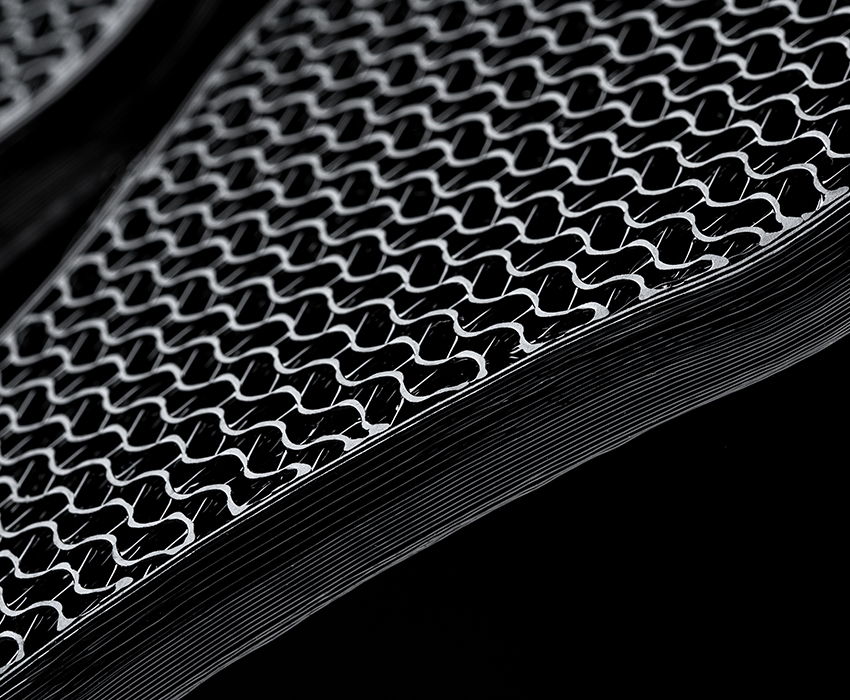

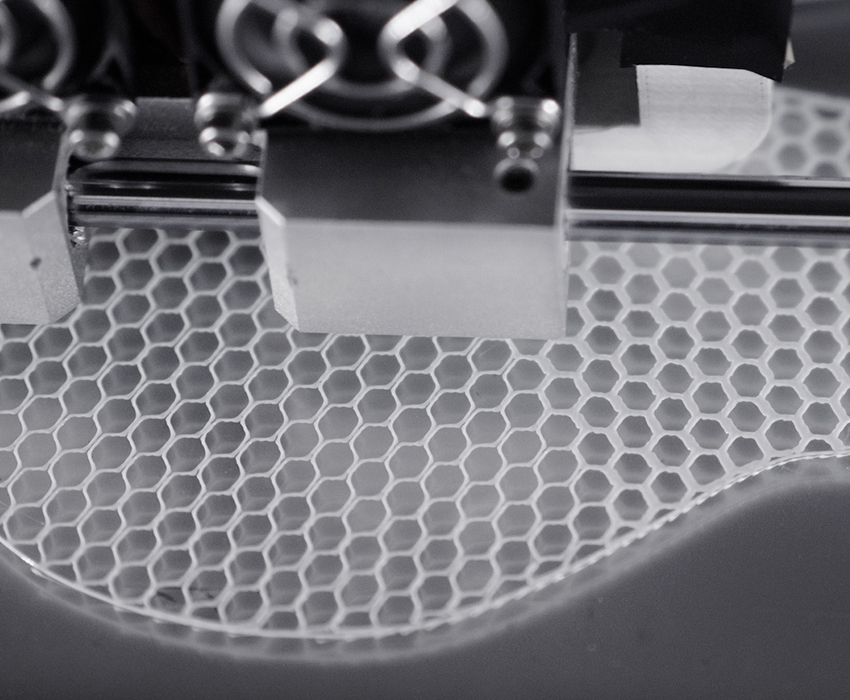

In the recent Eurobike 2022, we introduced 3D printing in cycling padding inserts with the Elastic Interface® N3X technology. The product and all the research around it aim not just to guarantee the performance of the cyclist but to also find a solution to produce them with zero production waste. By going beyond the available technology in the market, we were able to engineer a new way of production.

Why the Elastic Interface® N3X Technology is the game-changer?

Tailor-made Protection

We studied the structure of polyurethane foams first: we looked into their limits and the advantages we wanted to obtain from the new material to create a new structure that would give us the desired performance. By using 3D printing, we are able to control the technical characteristics of the foam padding, allowing us to fully customize how the chamois supports the cyclists in different areas in the saddle.

Long-lasting Performance & Temperature Control

Having total control over the structure of the material, this technology also gave us total control over the protection and support provided to the cyclist. Elastic Interface® N3X technology gives us more confidence to say that we guarantee enhanced saddle stability, complete freedom of movement, breathability, and moisture management.

Low Impact on the Environment

Finding a technology that solves the limit of the materials we used in a sustainable way is also a driver in this research. To produce our products with zero production waste is and will always be a goal we intend to reach. The N3X technology for paddings allows us to print only what we need where we need it, and with bio-based materials. The result is a zero-waste production for this kind of padding, and a reduced enviromental impact of raw materials.

At Elastic Interface®, all our work gravitates towards guaranteeing three components of comfort for every cyclist: extended support, stability on the saddle, and breathability. And with the N3X technology, we are able to deliver this in a sustainable way. Indeed, we have created the third dimension of comfort with this technology.